FEATURED SOLUTIONS

Why World Class Industries

How we differentiate ourselves from other companies

SCALABILITY

Our experience and expertise allow us to be nimble, adjusting resources quickly and in a cost-effective manner.

SIMPLICITY

We are built to streamline assembly processes, simplifying production and reducing your reliance on manpower.

ANALYSIS

Built on insight, informed by experience, and backed by analytics, our continuous improvement focus seeks to optimize all steps of the process.

FEATURED CASE STUDY

How We Improved Efficiencies

Our customer is a global OEM that specializes in manufacturing construction, agricultural, ground maintenance, and industrial vehicle equipment.

Background & Situation

The customer was line-side assembling hoods in their own factory but was facing numerous challenges.

- With hoods stored outdoors, they were exposed to the elements

- Their outdated production relied too heavily on manpower

- Inefficiencies in storage created material handling problems for assembly

- Significant amount of factory space was consumed for both storage of inventory and the assembly process

WCI Solutions

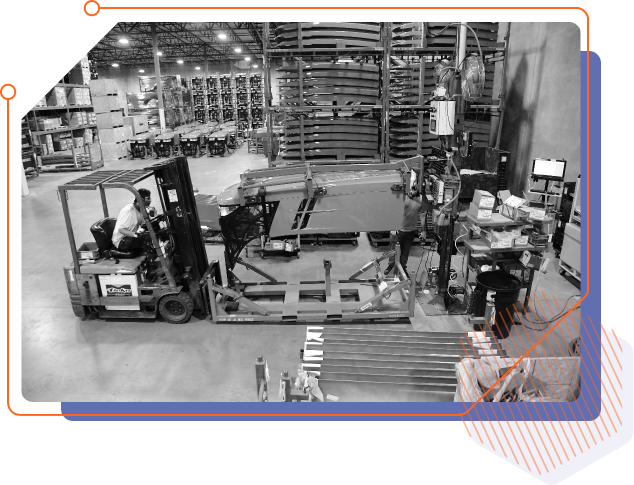

For nearly two decades, WCI has handled the assembly, testing, and sequencing of hoods for this manufacturer.

- Improved product quality and space-saving benefits for customer

- State-of-the-art technology simplified complex production

- Hoods arrived to customer tested and ready to go